Breath-Activated Inhaler with AVR

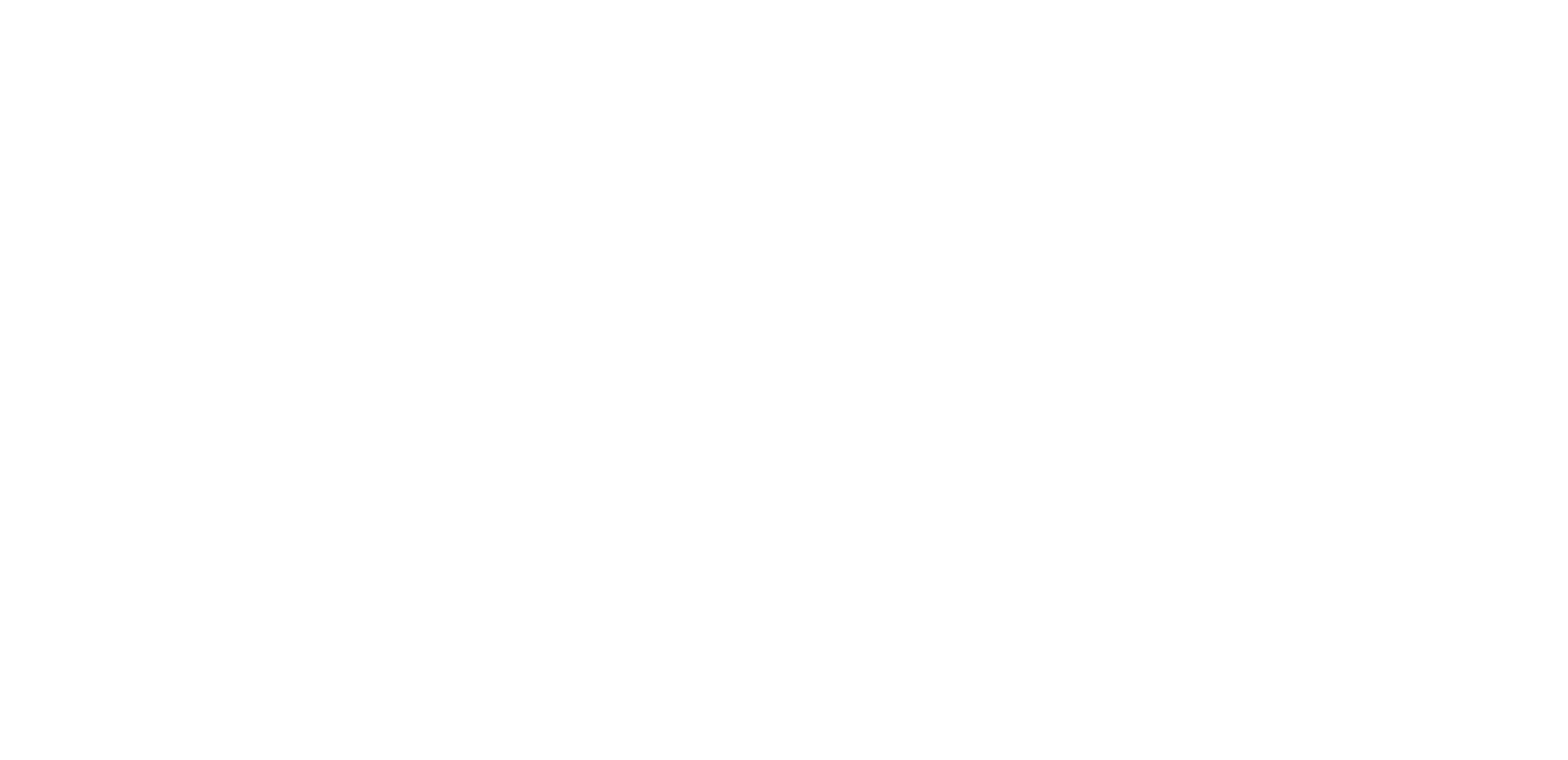

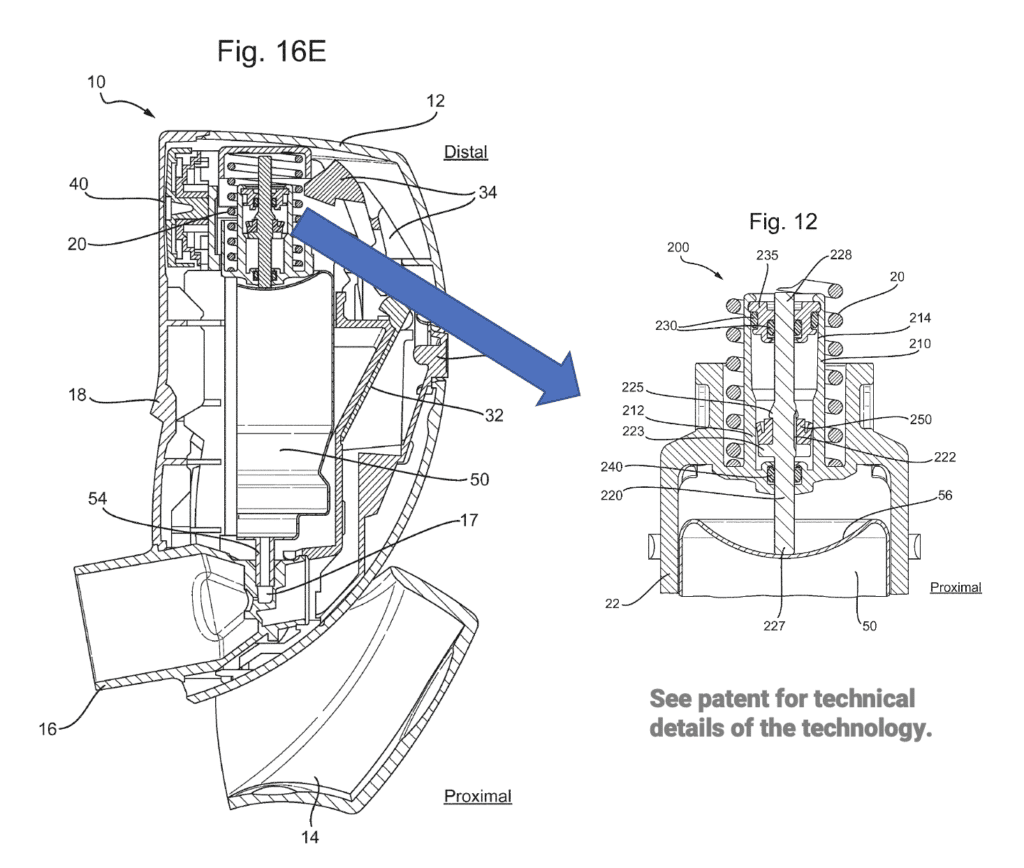

Granted Patent EP2109/05521 of Treneman et al, assigned to Astra Zeneca Plc describes how an automatic valve return (AVR) system for the pMDI propellant valve was built-in to an already complex BAI device.

This AVR system was required to promote uniform dosing under all operating conditions.

The UPC project took two years to complete from start-up, ending at full design freeze for manufacture after a large pilot build and design verification programme.

Breath-Activated Inhaler with AVR

Granted Patent EP2109/05521 of Treneman et al, assigned to Astra Zeneca Plc describes how an automatic valve return (AVR) system for the pMDI propellant valve was built-in to an already complex BAI device.

This AVR system was required to promote uniform dosing under all operating conditions.

The UPC project took two years to complete from start-up, ending at full design freeze for manufacture after a large pilot build and design verification programme.

We were proud to succeed where the others had failed.

Prudence went through three formal review stages to get from concept to production ready tooling and assembly machines.

The uniformity of performance was achieved by attention to detail during the design and tooling phases.

The maths model predictions where proven pessimistic, due to material changes at temperature not included in the assumptions. Serendipity is wonderful at the final hurdle.

A great device for patients, that remains waiting for the right therapy and time in the customers portfolio.

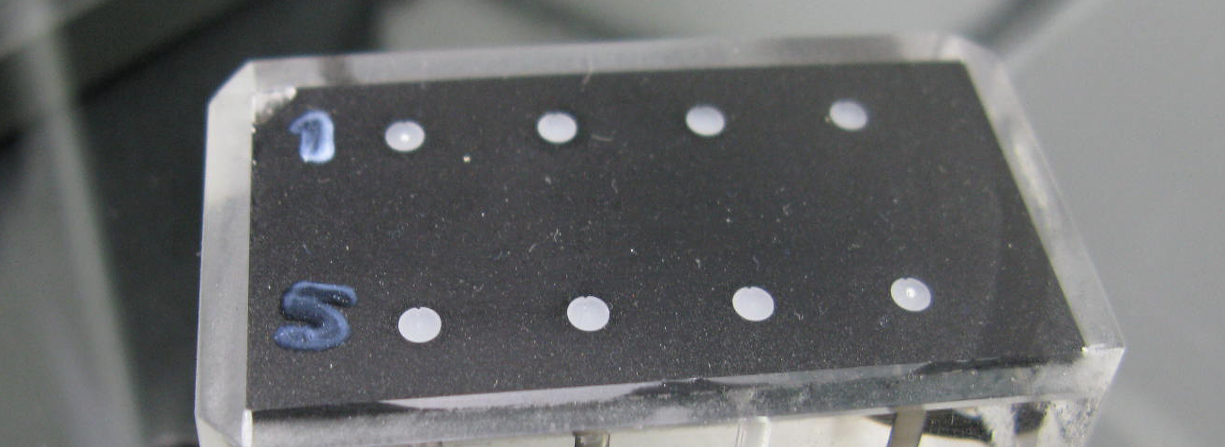

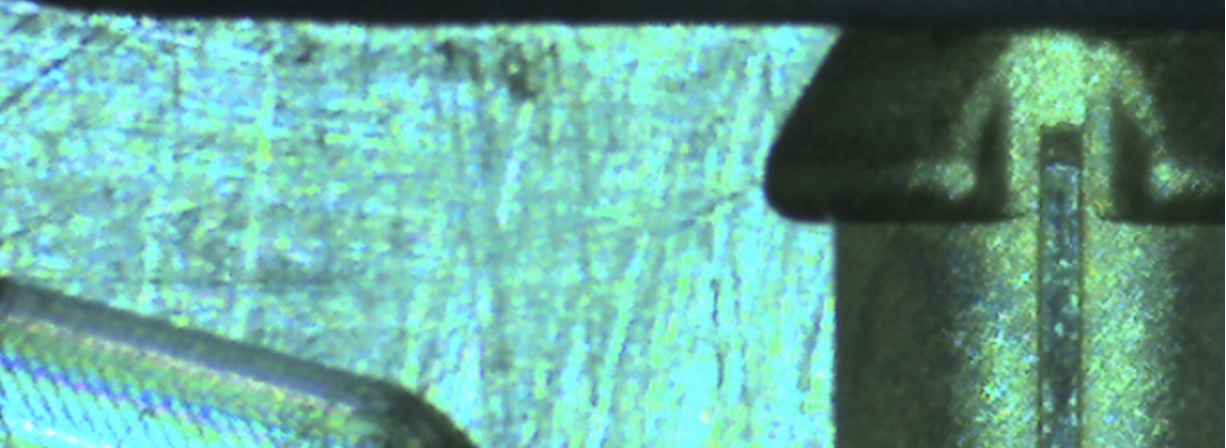

Detail moulding metrology

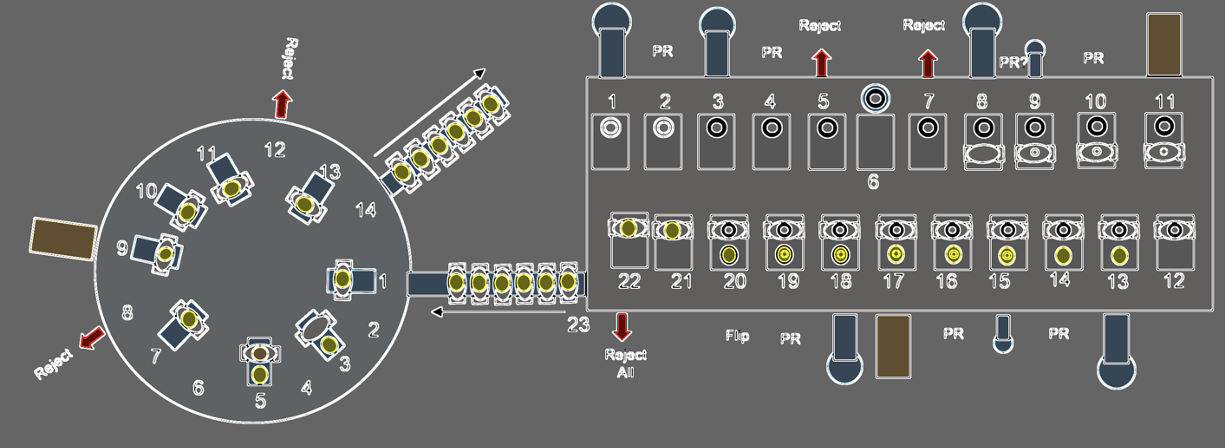

Assembly machine scheme

Detail tooling metrology

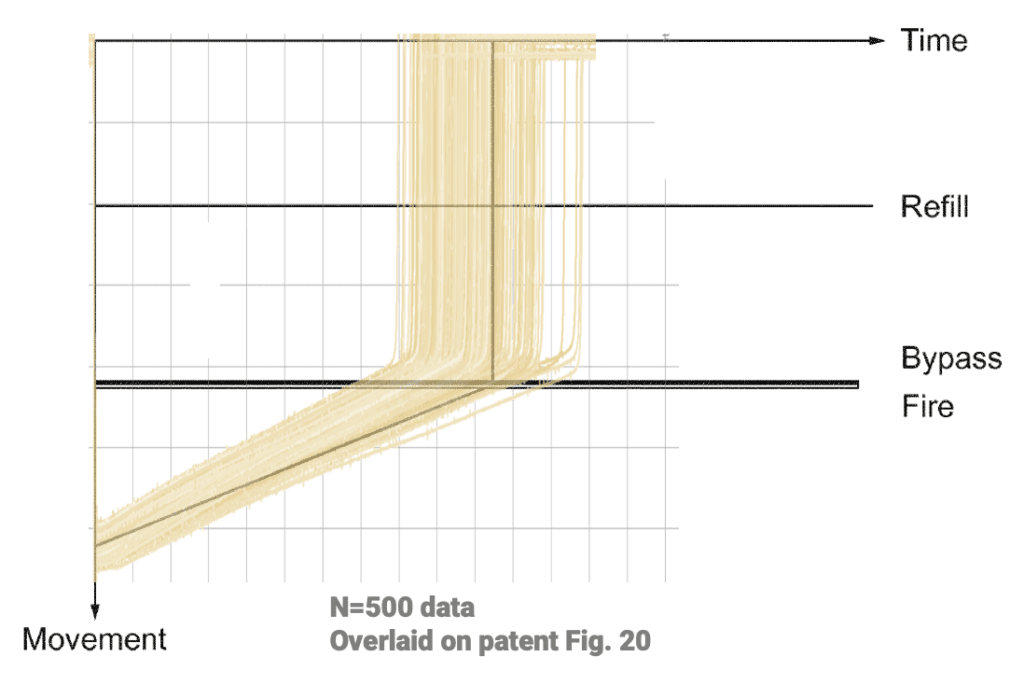

Proving CTQ performance on a statistically relevant sample size.

UPC built a pilot batch of fully engineered products for testing both during build at the sub assembly level, but also replicating batch release testing methods.

The graph on the left shows how the release data looks for n=500 units compared with the required nominal function line described in detail in the patent.

You may notice that there are 4 out of 500 outliers on the right hand and lower side of the graph (see sand coloured lines).

These four products were dis-assembled under controlled conditions and the root cause of the changed performance identified as plastic bag debris when opened without a cutter.